How to glue on liquid nails

In modern construction, there are many such materials that began to be used not so long ago. This is especially true for various kinds of dry mixes, modern adhesives, and paints and varnishes. Their use primarily increases the quality of work, and secondly, the drying time is reduced, thereby accelerating the process of work.

One such versatile material is liquid nails. This is an adhesive which, due to its properties, can be used for bonding various surfaces. And very often they began to replace fixing materials (screws, nails, self-tapping screws), namely with "liquid nails".

How to use liquid nails

What is the proper use of liquid nails? The basic rules that you must follow when working with liquid nails are as follows:

- before applying liquid nails, the surface must be cleaned and degreased; for this, any detergents can be used;

- the surface should be dry, hard, free of dust, dirty and greasy stains;

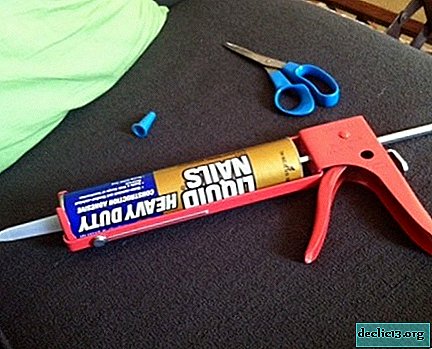

- glue is applied using a special gun or squeeze out the contents manually;

- apply liquid nails to the surface in stripes or single dots;

- After applying the product, carefully press objects against each other. For large objects (MDF panels, kitchen apron, etc.) you can use a mallet (rubber or wooden);

- fix the objects to be glued for a few minutes so that the glue “seizes”;

- after completion of work, use solvent or acetone to remove the remnants of the product;

- Use extreme caution, as solvent may damage the surface.

There are some compositions of liquid nails, the use of which is carried out according to the following scheme:

- an adhesive is applied to the surface of the item;

- strongly pressed to the surface;

- after that, the item is removed;

- after 10 minutes (during this time the glue thickens a little, but does not dry completely), it is pressed again and waiting until the agent completely dries.

Application area

The list of materials with which you can work with liquid nails is quite wide:

- plastic;

- glass;

- aluminum;

- wood;

- fiberboards;

- ceramic and polymer tiles;

- drywall;

- natural cork and so on.

Sometimes liquid nails are used as a sealant. They make sealing of various window structures, bathrooms, door frames and other elements in construction.

But still, it is best if you use liquid nails, according to the present instructions attached to them.

Main ingredients

The main composition of liquid nails includes chemical ingredients - polymers and synthetic rubber. In the role of a filler, a rather rare clay with a high plasticity index acts. Such clay is mined in America, and the main production facilities for the manufacture of these products are also located there.

Other manufacturers use chalk instead of clay. But this is not always justified, since the adhesion strength of the surfaces decreases. Chalk gives white color to liquid nails, when in order to get white color from liquid nails, where the filler is clay, titanium dioxide must be added.